- Moving Probe Tester

MicroCraft's diverse lineup of probes meets a variety of demands, including low dents.

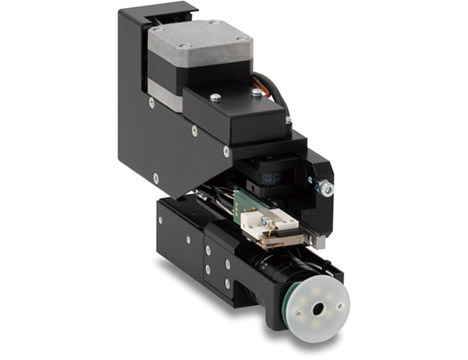

High Speed and High Accuracy Moving Probe Unit

Type10 Probe

The Type 10 probe is constructed of lightweight materials, with every detail reconfigured to accommodate high-speed inspection. High-speed probing is achieved by setting the drive speed to maximize the torque performance of the on-board motor.

Digital PPC (Probe Pressure Control)

MicroCraft’s push-pressure inspection mechanism, which has an established reputation for stable contact, uses digital PPC (Probe Pressure Control), which simplifies even the adjustment process. When replacing a probe, the probe is installed according to the device’s instructions, and the device then begins inspection at the specified pressure without adjustment. All G models in this catalog are equipped with this system as standard.

Type9 Probe

Built-in Encoder

Type 9 probe is the standard probe* of the S series (ultra-high precision type). An encoder is built into the motor, and smooth control by feedback from the encoder ensures reliable probing from low to high speed ranges. A unique speed setting allows the speed to be increased while maintaining a low strike. Digital PPC is also included.

* Models other than the S series are optional equipment.

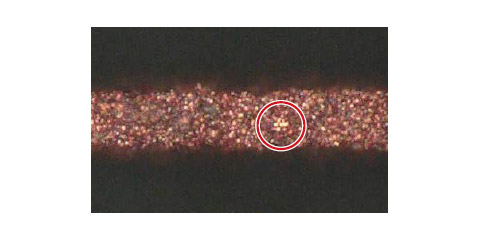

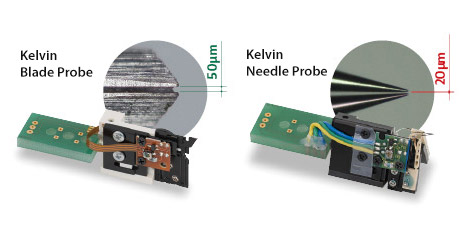

Witness mark when contacting 20µm pad

Witness mark when contacting 20µm pad

Enhanced Rigidity of Probe

Probe is the final part to complete the precise positioning, however it is also the part that is influenced by numerous external factor. For example, temperature is one of these factor. MicroCraft have reconsidered all material and modified the design of the parts used to build the probe in order to enhance the rigidity and thus be insulates from the influence of external factor.

One Screw Replacement

With our new cartridge design, users can now easily change tips as required to achieve optimum results. Most importantly the touch down sensor which allows unparalleled performance in testing flexible boards, highly warped PCB's, cavities and different heights on surface.

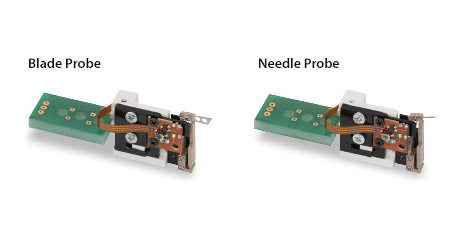

Probe Tip Lineup

Probe Tip

Two types of probe tips are available: “Blade” type is suitable for standard boards allowing stable probing with through holes, while “Needle” type is suitable for fine pitch boards such as BGAs.

Kelvin Probe Tip Optional

For low resistance measurements, Kelvin probes are also available. Kelvin probe needle tips achieve 20 µm pitch between the two contacts and allows testing of the C4 bumps on package boards.

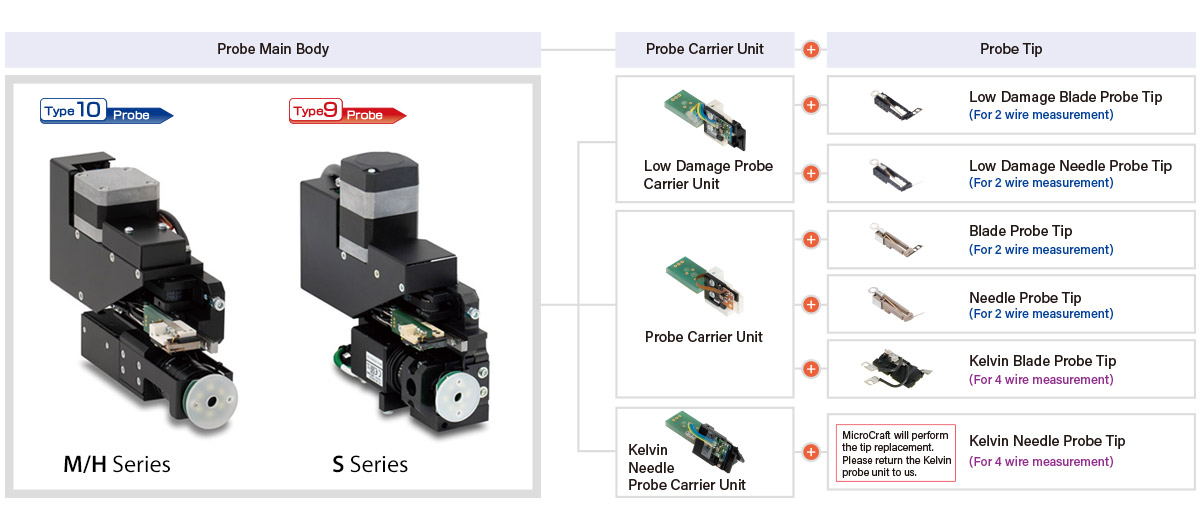

Probe Configuration

Probe Main Body: Installed to EMMA

Probe Carrier Unit: A common carrier to which the probe tip is mounted.

Probe Tip: The probe tip can be attached to the carrier unit and used as a probe unit.

* Please refer to our "Probe Catalog" for the model number of the probe tip. Please contact our sales representative for the probe catalog.

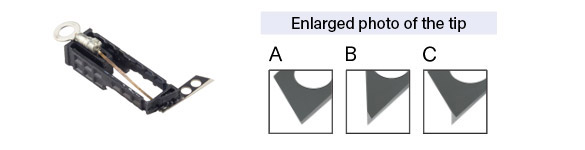

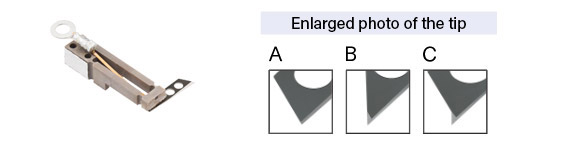

Low Damage Blade Probe Tip

A. Low Damage Blade / B. Low Damage Pointed V-Acute Blade / C. Low Damage Stepped-Steep Blade

Used for the boards with thruhole. The dents on the board can be smaller than those of standard blades.

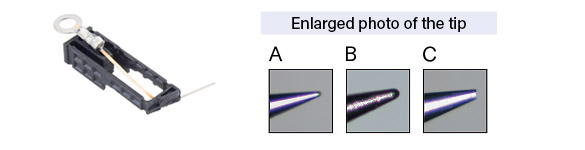

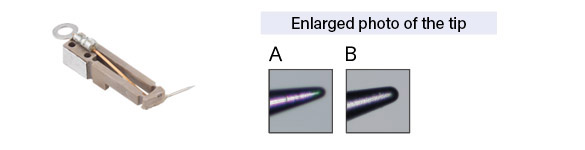

Low Damage Needle Probe Tip

A. R10 Low Damage Needle / B. R20 Low Damage Needle / C. Flat 30 Low Damage Needle

Used for boards with no thruhole. The dents on the board can be smaller than with a normal needle.

Blade Probe Tip

A. Standard Blade / B. Pointed V-Acute Blade / C. Stepped-Steep Blade

Used for boards with thruholes as test point

Needle Probe Tip

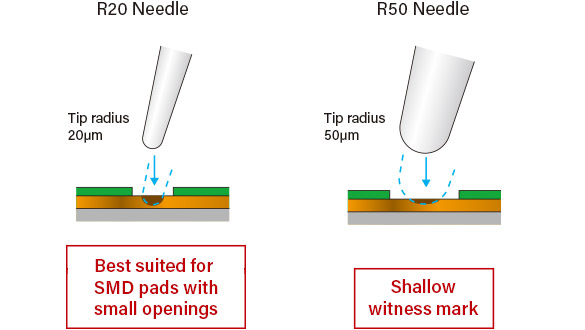

A. R20 Needle / B. R50 Needle

Used for boards with no thruhole. More capable of testing fine pitch boards compared to the blade.

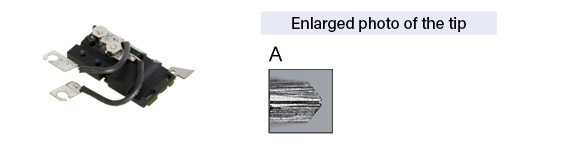

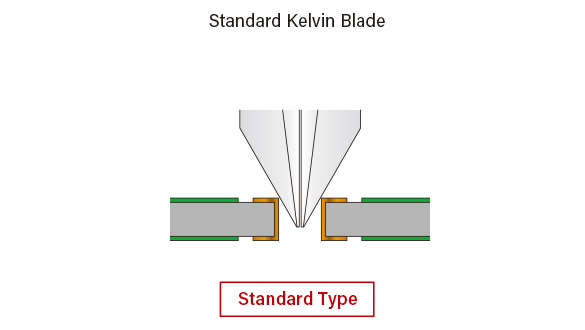

Kelvin Blade Probe Tip

A. Standard Kelvin Blade

Used for 4-wire testing on the boards with thruholes

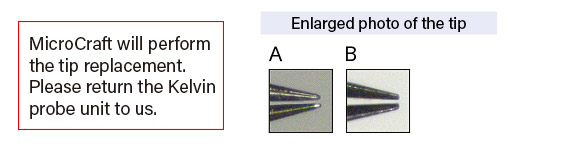

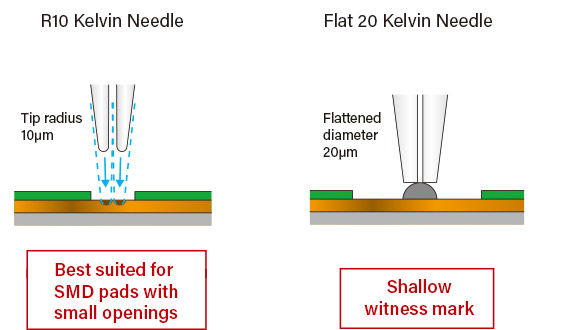

Kelvin Needle Probe Tip

A. R10 Kelvin Needle / B. Flat 20 Kelvin Needle

Used for 4-wire testing on the boards with fine pads

Comparison of Probe Tip

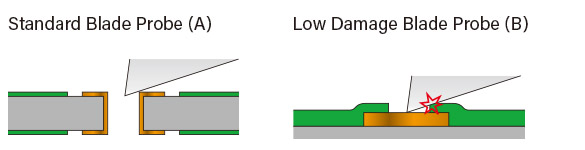

Difference between blade probe/low damage blade probe tip.

It is able to make stable contact with thruholes. However, when overlapping of solder resist are present, blade may come in contact with solder resist while testing. In addition, (A) and (B) shares the shame blade shape, however (B) having the probe tip design for low pressure, witness mark is small compared to (A).

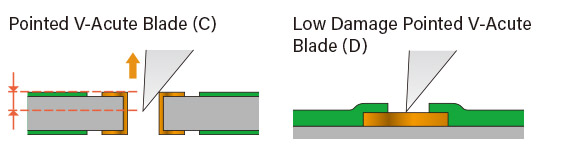

It is able to test pads of small opening with overlapping solder resist without the blade coming in contact with solder resist. However, if large thruholes are present, it is necessary to increase the probe height. In addition, blade form of (D) is same as a V-Acute blade (C), but it shall leave smaller witness mark due to the blade tip designed to give lower contact pressure.

It is able to test pads with small opening by overlapping solder resist without the blade coming in contact with solder resist. In addition, when large thruholes are present, probe height can be made smaller compared to V-Acute blade probe. Furthermore, blade form of (F) is same as a Stepped-Steep blade (E), but it shall leave smaller witness mark due to the blade tip designed to give lower contact pressure.

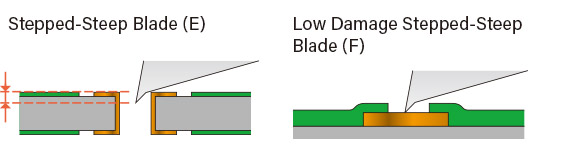

Difference between the low damage needle probe tip.

R10 Low Damage Needle

Extremely small witness mark area.

R20 Low Damage Needle

Shallow witness mark compared to R10 Low Damage Needle.

Flat 30 Low Damage Needle

Suitable for bumps and tall pads that tip may slide.

Difference between needle probe tips.

R20 Needle

Small witness mark area.

R50 Needle

Shallow witness mark area.

Blade kelvin probe tips

Standard Kelvin Blade

Standard Kelvin Blade

Difference between needle kelvin probe tips.

R10 Kelvin Needle

Extremely small witness mark area.

Flat 20 Kelvin Needle

Suitable for bumps and tall pads that tip may slide.