System Integration

MicroCraft is proud to achieve, maintain, and operate under the guidelines of ISO 9001. Product quality is controlled from planning through designing and manufacturing to the final testing. This insures our products to be of the highest quality and reliability.

Planning

Customer and market needs are reviewed and analyzed for the next generation of products.

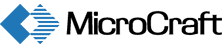

- Electronics -

MicroCraft’s extensive knowledge accumulated through years of experience is now equipped with latest CAD system to enables us to design PCBs with high speed circuitry, logic simulation and real time modeling.

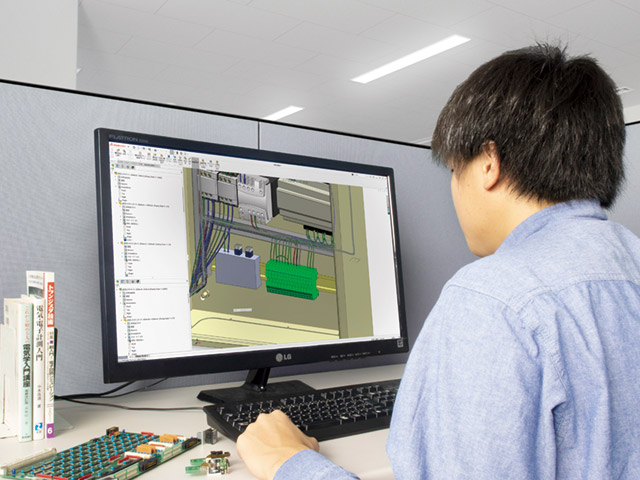

- Mechanical -

Our internal mechanical design department insures all mechanical assemblies and sub-assemblies are meeting our design standards for high speed, resolution and dependability.

- Software -

From operating systems and applications to firmware implementation, our software designers are unparalleled. Integration between electronics, mechanical, and software departments insures products perform to their highest potential.

Design

Manufacturing

All parts and sub-assemblies are carefully selected and inspected before assembly. The new manufacturing plant allows us to carefully integrate all the parts to make products that are of the highest quality and reliability.

- Ink Development -

Through many years of experience, testing has been proven to be most important. Our systems go through strict (ISO 9001 regulated) testing and burn-in prior to shipment. All history and testing results are electronically stored for customer support and field technician access.

Testing

Review

After designing, manufacuring and testing, detailed reviewing process begins to ensure that all specifications and requirements are met.

Exhibiting our products in local and international trade shows (Japan, USA, Europe, China, Taiwan, Korea, India) allows us to display our products and gather market needs and other associated informations.

Trade Show