- On-demand InkJet Printing System

CraftPix has superior mechanical attributes that has made high production performance possible.

Exceptional attributes accomplished high speed and accurate printing with maintaining low environmental risk.

Mechanism

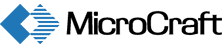

UV Curing Lamp (High speed immediate curing)

On-head UV lamps (LED UV lamps *1) equipped on the side of the print head for curing the ink while printing. C8K and C4K models are equipped with 8 and 4 dedicated on-head UV lamps, respectively, for each print head.

*1 LED UV lamp to be mounted depends on the ink to be used.

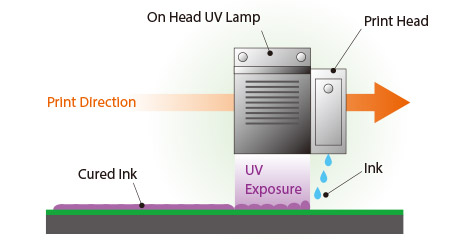

Automatic Ink Recycling

Ink discharged at cleaning purge operation is filtered and reused. Ink waste is reduced to less than 1%, keeping the running costs to an absolute minimum.*2 C8K/C4K/C2K**T models are equipped with two ink recycling systems to recycle two types of ink. (Not installed in Small Volume type)

*2 Ink recycle system may be unusable depending on the ink selected.

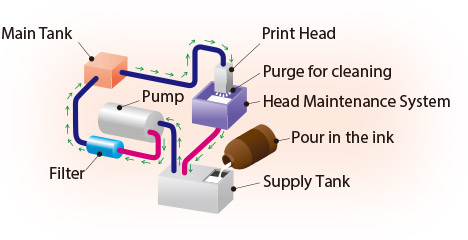

Head Maintenance System

The print array surface is now cleaned with automatic lint free roller. Conventional manual cleaning procedures are no longer required with fully automated system, which delivers a clean wipe to clean the print head.

A: “Purge station” for maintenance by suction method.

B: “Wipe station” for cleaning the nozzle surface.

Nozzle surface is cleaned with a roll of cleaning wipes. This eliminates the need of tedious manual replacement of cleaning wipes, and automatically rolls the dirty wipes and supplies fresh ones. The wipe removes ink droplets and dust off the nozzle surface with a light touch that does not damage the print head. This helps maintain the condition of the nozzle surface in a stable manner.

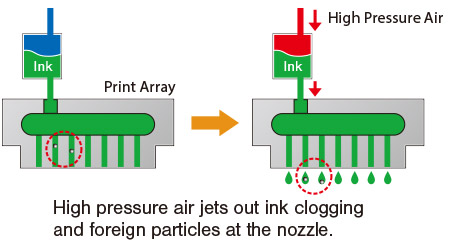

Automated Air Purge System

Automated air purge system using high pressure helps prevent nozzle clogging. This operation can be implemented while machine is idle, such as when the operator is swapping panels so that print time is not affected.

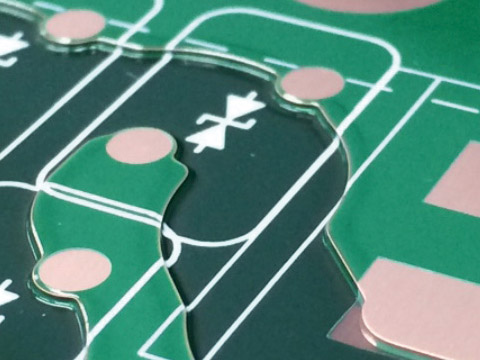

High Contour and Thick Trace Printing.

Drop on demand inkjet printing allows uneven surface printing (difference of approximately 400+ µm) while conventional silk screen system fails with big stepping and skips printing.