- Moving Probe Tester

Accomplishes greater probing accuracy compared to standard model

Suitable for testing high-density and fine-pitch boards

H Series (4 Probe System)

High Accuracy Model

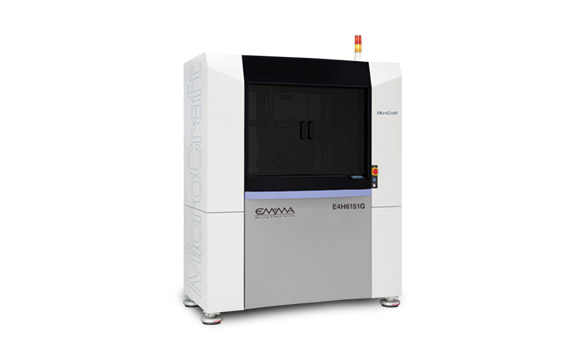

E4H6151G / E4H3325G NEW

Dramatically improved probing accuracy to test high density fine pitch boards that were not testable with the standard model. E4H6151G corresponds to testing standard sized boards with up to min. pad size of 20µm and min. pad pitch of 50µm. Whereas E4H3325G is specifically designed for testing high density general module and mother boards with up to min. pad size of 15µm and min. pad pitch of 45µm.

Detailed Specification

| E4H6151G | E4H3325G | ||

|---|---|---|---|

| Max. Test Area | 24 x 20” (610 x 510 mm) |

13 x 9.8” (330 x 250 mm) |

|

| Number of Probes | 2 Front, 2 Rear |

2 Front, 2 Rear |

|

| Min. Board Size | 2.4 x 2.6” (60 x 65 mm) |

1.6 x 1.4” (40 x 35 mm) |

|

| Max. Board Thickness | 0.354” (9 mm) |

0.354” (9 mm) |

|

| Untestable Area | 1 mm from edge of clamp area *1 |

1 mm from edge of clamp area *1 |

|

| Repeatable Accuracy *2 | ±0.16 mil (±4 µm) |

±0.08 mil (±2 µm) |

|

| Resolution | 0.08 mil (2 µm) |

0.04 mil (1 µm) |

|

| Min. Pad Pitch | 2.0 mil (50 µm) *3 |

1.8 mil (45 µm) *3 |

|

| Min. Pad Size | 0.8 mil (20 µm) *4 |

0.6 mil (15 µm) *4 |

|

| Test Voltage | Continuity Test: 0–10 V |

Continuity Test: 0–10 V |

|

| Test Current | Continuity Test: 2.5 µA–150 mA |

Continuity Test: 2.5 µA–150 mA |

|

| Clamp System | Pneumatic Clamp |

Pneumatic Clamp |

|

| Alignment Camera | 2 Front, 2 Rear |

2 Front, 2 Rear |

|

| Printer | External |

External |

|

| Air Supply: Pressure | 0.5 MPa |

0.5 MPa |

|

| Air Supply: Volumetric flow rate | 0.12 ft³/min. (3.5 ℓ/min.) |

0.12 ft³/min. (3.5 ℓ/min.) |

|

| Power Supply *6 Single Phase AC200–240 V 50/60 Hz |

10 A |

10 A |

|

| Weight | 2535 lbs. (1150 kg) |

2646 lbs. (1200 kg) |

|

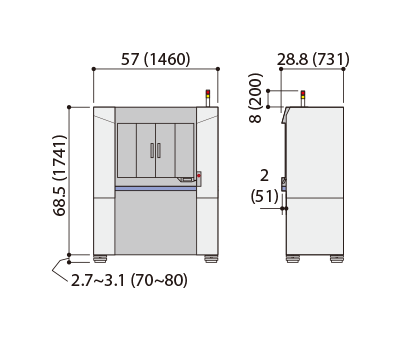

| Dimensions [ unit: inch(mm) ] |

|

|

|

| Required System | 1)Control PC & Monitor 2)PC & Monitor for Test Data Editing. * 1) and 2) can be completed in one PC. * Please inquire our sales for PC specification. |

||

| Software | EMMA2020 for Control PC is included, but all other software is optional (supporting OS are Windows 10 / Windows 11) | ||

| Probe Type | Different types of probes were designed to address specific needs. Please contact our sales for more information on each probe types in selecting ideal probe. | ||

| Operating Conditions | 70–75°F (21–24°C), 30–70% relative humidity * Do not use under the environment that has heavy condensing, dust, vibration, and/or corrosive gas. Atmospheric Dew Point: −14°C or below (at 0.7 Mpa, dew point is 15°C or below) Oil Mist Concentration: 1 mg/㎥ (ANR) or below |

||

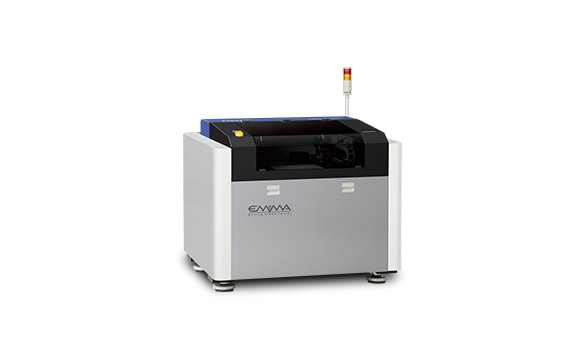

H Series (2 Probe System)

High Accuracy Model

F2H6151G / F2H3325G NEW

Flatbed type with a horizontal vacuum table to secure the substrate. F2H6151G corresponds to testing standard sized boards with up to min. pad size of 20µm and min. pad pitch of 50µm. Whereas F2H3325G is specifically designed for testing general module and high density mother boards with up to min. pad size of 15µm and min. pad pitch of 45µm.

* Door design may defer depending on the specification.

Detailed Specification

| F2H6151G | F2H3325G | |

|---|---|---|

| Max. Test Area | 24 x 20” (610 x 510 mm) |

13 x 9.8” (330 x 250 mm) |

| Number of Probes | 2 Upper |

2 Upper |

| Min. Board Size | 2 x 2” (50 x 50 mm) |

2 x 2” (50 x 50 mm) |

| Max. Board Thickness | 0.4” (10 mm) |

0.4” (10 mm) |

| Untestable Area | — |

— |

| Repeatable Accuracy *1 | ±0.16 mil (±4 µm) |

±0.08 mil (±2 µm) |

| Resolution | 0.08 mil (2 µm) |

0.04 mil (1 µm) |

| Min. Pad Pitch | 2.0 mil (50 µm) *2 |

1.8 mil (45 µm) *2 |

| Min. Pad Size | 0.8 mil (20 µm) *3 |

0.6 mil (15 µm) *3 |

| Test Voltage | Continuity Test: 0–10 V |

Continuity Test: 0–10 V |

| Test Current | Continuity Test: 2.5 µA–150 mA |

Continuity Test: 2.5 µA–150 mA |

| Clamp System | Vacuum Plate |

Vacuum Plate |

| Alignment Camera | 2 Upper |

2 Upper |

| Printer | External |

External |

| Air Supply: Pressure | 0.5 MPa |

N/A |

| Air Supply: Volumetric flow rate | 0.02 ft³/min. (0.6 ℓ/min.) |

N/A |

| Power Supply *5 Single Phase AC200–240 V 50/60 Hz |

8 A |

8 A |

| Weight | 1587 lbs. (720 kg) |

1543 lbs. (700 kg) |

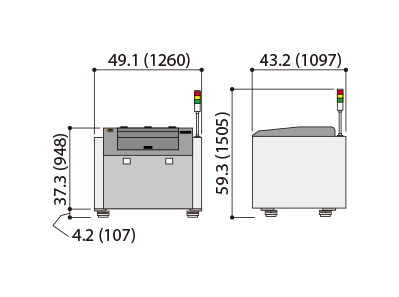

| Dimensions [ unit: inch(mm) ] |

|

|

| Required System | 1)Control PC & Monitor 2)PC & Monitor for Test Data Editing. * 1) and 2) can be completed in one PC. * Please inquire our sales for PC specification. |

|

| Software | EMMA2020 for Control PC is included, but all other software is optional (supporting OS are Windows 10 / Windows 11) | |

| Probe Type | Different types of probes were designed to address specific needs. Please contact our sales for more information on each probe types in selecting ideal probe. | |

| Operating Conditions | 70–75°F (21–24°C), 30–70% relative humidity * Do not use under the environment that has heavy condensing, dust, vibration, and/or corrosive gas. Atmospheric Dew Point: −14°C or below (at 0.7 Mpa, dew point is 15°C or below) Oil Mist Concentration: 1 mg/㎥ (ANR) or below |

|

- Please feel free to contact us for questions regarding the machine specs, quotes, inquiries for a brochure from the following phone number or the inquiry form. The equipment seen in the lineup are customizable to address your needs.

-

- Inquiries by phone

+1-714-482-2550 - Inquiries by email

Inquiry form

- Inquiries by phone