- Moving Probe Tester

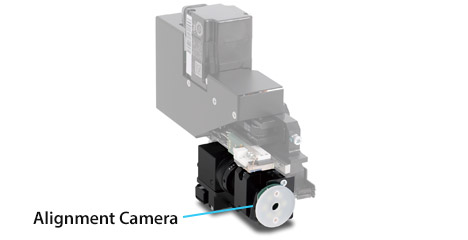

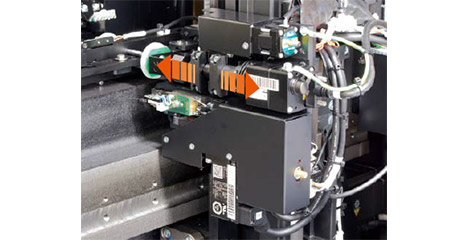

EMMA is equipped with high sensitivity Alignment cameras

for accurate positioning of the probes.

Alignment Camera

2 Types of Alignment Cameras

All MicroCraft Testers are equipped with high magnification Alignment cameras to ensure the best possible alignment and targeting. By affixing a camera to each probe head, MicroCraft ensures that each probe head is individually aligned and accurate. The camera’s image is analyzed and processed with MicroCraft’s advanced image processing software and the appropriate adjustments and corrections are made instantly. This allows compensation for x, y and theta inaccuracies as well as side to side miss-registration. There are two types of cameras available on MicroCraft EMMA systems and the most suitable camera shall be equipped according to board types and testing performed.

| Specifications | Type E (for M series) | Type H (for H/S series) |

|---|---|---|

| Interface | Analogue |

Digital |

| FOV (mm) | 4.2 x 3.1 |

5.0 x 3.7 |

| Resolution (µm/pixel) | 6.6 |

3.45 |

Motorized Focus Mechanism Optional

The motorized focusing mechanism is available as an option. With this feature, each camera’s movements in z-axis direction is strictly controlled by the motor power. This eliminates the time and effort normally required to adjust focus manually. The operator is only required to enter the board thickness of the board being tested. The camera then moves automatically to adjust the focus. Mechanical tools are no longer needed in the process. Entered board thickness for each test board is saved as a part of the test settings, so that camera can automatically returns to the previous saved position if the setting is available. If required, you can also use EMMA’s touch panel to make quick fine adjustments to each camera’s focus.